Small ovens burn bottoms because heat isn’t evenly distributed, often caused by poor ventilation and hotspots near heating elements. Tray material plays a big role—thicker, conductive metals like aluminum help heat evenly, while thin trays can warp and cause uneven baking. Radiant heat from the bottom heats trays directly, leading to over-browning. Choosing the right tray and understanding this heat transfer can prevent burning, so explore the details to improve your baking results.

Key Takeaways

- Small ovens often have uneven heat distribution due to poor ventilation and hotspots near heating elements.

- Metal trays, especially thin ones, quickly absorb and emit infrared radiation, increasing the risk of over-browning or burning bottoms.

- Radiant heat directly transfers infrared energy to tray bottoms, which can cause uneven heating if trays are poor conductors.

- Tray material and thickness influence heat transfer, with thinner or reflective trays leading to localized hot spots.

- Proper tray placement, material choice, and oven maintenance help mitigate radiant heat effects and prevent burnt bottoms.

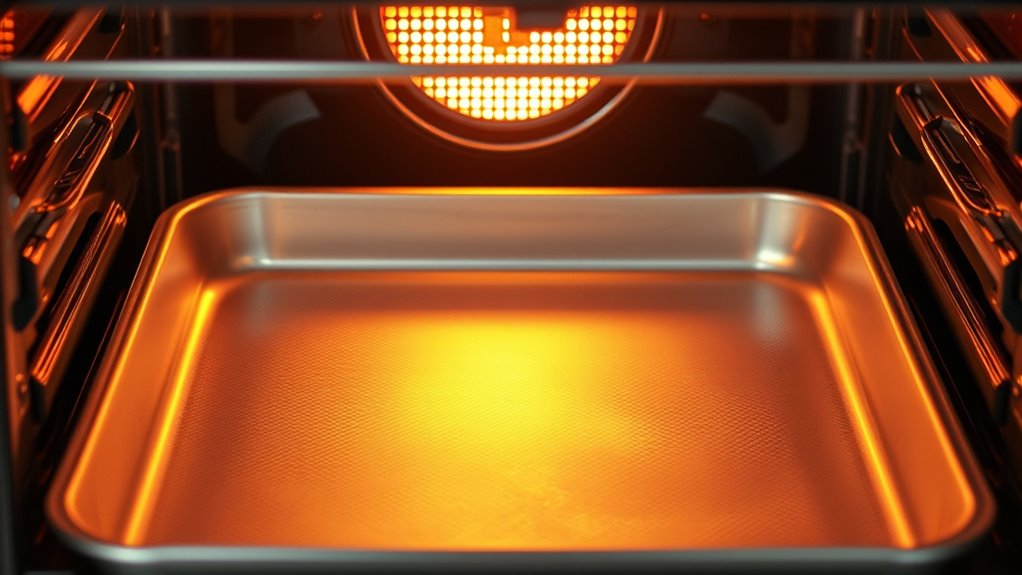

How Small Ovens Distribute Heat Differently

Small ovens often distribute heat unevenly, which can cause your baked goods to burn at the bottom while remaining undercooked elsewhere. This uneven heat distribution primarily results from poor oven ventilation and irregular airflow patterns. When airflow isn’t properly managed, hot air pools near the heating element, creating hotspots that directly impact the tray’s bottom. Limited ventilation can trap steam and heat inside, causing inconsistent temperatures across the oven chamber. As a result, some areas may overheat, leading to burnt bottoms, while others stay undercooked. Understanding how airflow moves within your small oven helps you identify why certain spots get hotter. Improving oven ventilation or adjusting tray placement can promote more even heat distribution, reducing the risk of burning your baked goods. Proper airflow management is essential for achieving consistent cooking results in small ovens.

How Tray Material Affects Heat Conductivity and Baking

The material of your baking tray plays a significant role in how heat is transferred to your baked goods. Thicker trays generally conduct heat more evenly, reducing hot spots that can cause burning. Material durability also matters; sturdy metals like aluminum withstand high temperatures without warping, maintaining consistent heat transfer. Thinner trays heat quickly but may warp and lead to uneven baking. Consider this comparison:

| Tray Type | Tray Thickness | Material Durability |

|---|---|---|

| Aluminum | Thin | High |

| Steel | Thick | Very high |

| Non-stick | Varies | Moderate |

Choosing the right tray material and thickness helps control heat flow, minimizing burnt bottoms and ensuring even baking. Proper heat conduction plays a crucial role in achieving consistent results in baking.

How Radiant Heat Works and Its Effect on Bottom Browning

Radiant heat transfers energy directly from a heat source to the bottom of your baked goods, often causing browning or burning if not controlled. This process relies on infrared radiation, which emits heat in the form of electromagnetic waves. When these waves reach your tray, they transfer heat efficiently, affecting the bottom of your baked items. To understand this better:

- Infrared radiation penetrates the tray and heats its surface quickly, leading to rapid heat transfer.

- The intensity of radiant heat depends on the oven’s heating element and its proximity to your tray.

- Different tray materials absorb and emit infrared radiation differently, influencing how much heat reaches your baked goods.

- Using tray materials with better heat reflection or dispersion properties can help prevent over-browning and promote more even baking.

Controlling radiant heat helps prevent burnt bottoms and achieves even baking.

Which Tray Materials Impact Baked Goods Most

Different tray materials absorb and emit infrared radiation at varying rates, substantially impacting how evenly your baked goods cook. Metal trays like aluminum heat quickly and reflect heat, which can cause uneven browning or burning bottoms if they’re not well-designed. Cast iron offers excellent tray durability and retains heat well, promoting more uniform baking but can be heavy and less responsive to temperature changes. The tray size also matters—larger trays distribute heat more evenly, reducing hot spots, while smaller ones might concentrate heat and cause burning. Choosing the right material depends on your baking needs; durable materials like stainless steel ensure longevity, but their heat absorption varies. Additionally, material heat response plays a crucial role in how quickly and evenly heat is transferred to baked goods. When selecting a tray, consider heat transfer efficiency to optimize baking results. Ultimately, selecting a tray with suitable heat emission and appropriate size helps prevent burnt bottoms and promotes even baking. Understanding radiant heat can further improve your choice of tray material to achieve consistent baking outcomes.

How to Prevent Burnt Bottoms in Small Ovens

To prevent burnt bottoms in small ovens, you need to control heat distribution and baking techniques carefully. First, make certain your oven is clean, as built-up grease or residue can cause uneven heat. Second, pay attention to tray placement: position trays in the middle or higher racks to avoid direct heat from the oven’s bottom element. Third, consider using oven-safe mats or adjusting the oven temperature slightly lower to prevent direct radiant heat from burning the bottom. Regular oven cleaning maintains even heat flow and prevents hotspots. Additionally, rotating trays halfway through baking helps achieve uniform results. By managing tray placement and keeping your oven clean, you reduce the risk of burnt bottoms while improving baking consistency.

Frequently Asked Questions

How Does Oven Size Influence Heat Distribution Consistency?

You’ll notice that smaller ovens often have uneven heat zones, making heat distribution inconsistent. This happens because limited oven airflow struggles to circulate heat evenly, especially in tight spaces. Larger ovens tend to maintain more uniform temperatures because they promote better airflow, reducing hot and cold spots. So, oven size directly impacts heat distribution, and understanding how heat zones form helps you manage baking results more effectively.

Can Adjusting Oven Racks Reduce Burnt Bottoms?

Yes, adjusting your oven racks can help reduce burnt bottoms. Proper rack positioning guarantees even heat distribution, preventing hot spots that cause burning. Additionally, using trays made from heat-reflective materials like aluminum or ceramic can minimize radiant heat absorption, protecting your baked goods. Experiment with different rack heights and tray materials to find the ideal setup, and you’ll notice fewer burnt bottoms and more evenly baked results.

Are There Specific Tray Coatings That Prevent Burning?

Yes, there are tray coatings that help prevent burning. Look for trays with non-stick, heat-resistant coatings made from materials like silicone or ceramic. These coatings create a barrier between your baked goods and direct heat, reducing the risk of burning bottoms. By choosing trays with high-quality, heat-resistant materials and non-stick surfaces, you can achieve more even baking and keep your baked items perfectly cooked without scorching.

How Does Humidity Inside the Oven Affect Bottom Browning?

Humidity inside the oven influences bottom browning by controlling moisture retention. Higher humidity levels reduce excessive dryness, preventing the bottom from burning and ensuring even browning. By adjusting humidity control, you can maintain ideal moisture, which helps distribute heat more evenly across the tray. This balance allows baked goods to develop a golden crust without scorching, giving you better control over the final product’s appearance and texture.

What Role Does Oven Calibration Play in Preventing Burning?

Ever think your oven is secretly plotting against your baked goods? Proper oven calibration is your secret weapon. It guarantees your oven maintains temperature accuracy, preventing those pesky burnt bottoms. Regular oven maintenance keeps sensors and thermostats in check, so you don’t have to play the guessing game. When your oven’s calibrated right, you’re in control—no more burnt surprises, just perfectly baked treats every time.

Conclusion

To prevent burnt bottoms, prioritize proper tray choices and placement. By understanding how tray materials and radiant heat work together, you can master the art of even baking. Choose trays that conduct heat kindly, and position them thoughtfully to prevent scorching. With mindful methods and material mastery, you’ll melt away mishaps and enjoy perfectly baked treats every time—turning your tiny oven into a triumph of tasty, tender, and evenly baked delights.