When you preheat a material, thermal saturation can still stop it from reaching the highest temperature. This happens because the material’s heat absorption slows down as it nears its maximum capacity, and heat transfer limitations—like phase changes or decreased conductivity—kick in. Your system’s design and material choices also play a role. To understand how to navigate these limits and improve heating performance, keep exploring the key factors involved.

Key Takeaways

- Thermal saturation occurs when a material reaches its maximum temperature, limiting further heat absorption despite preheating.

- Heat capacity and molecular limits prevent temperature increases even after additional energy input.

- Inefficient heat transfer methods or poor insulation can hinder reaching the desired temperature during preheating.

- Material properties, such as decreased thermal conductivity at high temperatures, contribute to early saturation.

- Proper system design, sensors, and enhanced heat transfer techniques are needed to overcome saturation and achieve higher temperatures.

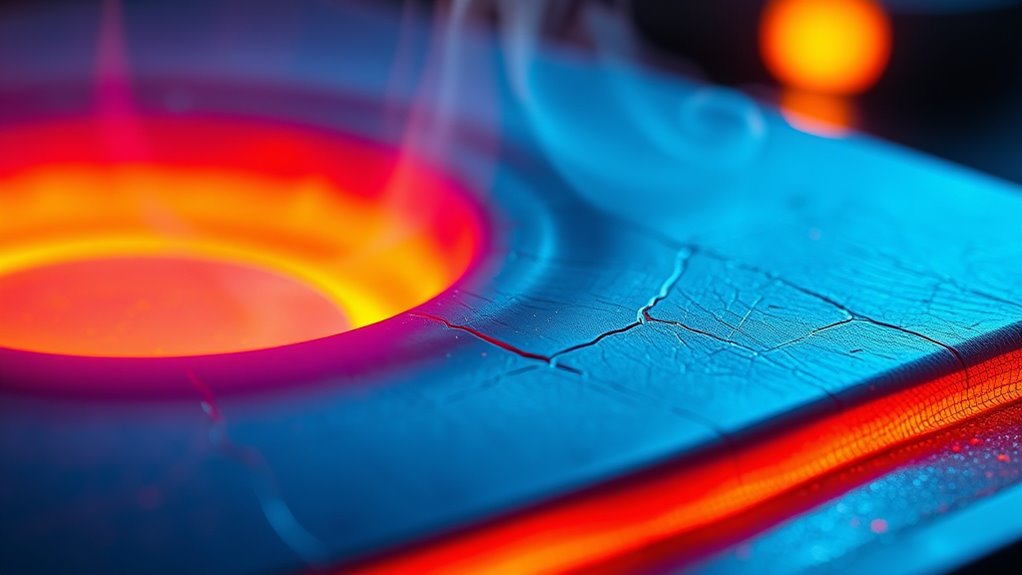

What Is Thermal Saturation and How Does It Limit Heat Transfer?

Thermal saturation occurs when a material or system reaches a temperature point where it can no longer absorb or transfer additional heat effectively. At this stage, molecular dynamics slow down as molecules approach their maximum vibrational energy, limiting further heat transfer. Your material’s heat capacity plays a vital role here; it determines how much heat is needed to raise its temperature. Once the material reaches saturation, additional heat doesn’t substantially increase the temperature because the molecules are already in their highest energy states. This phenomenon effectively caps heat transfer, preventing further temperature rise. Heat transfer efficiency is also affected during saturation, which is why simply adding more heat won’t necessarily make it hotter beyond this point. Understanding thermal saturation helps you recognize when a system has reached its thermal limit, highlighting that simply adding more heat won’t necessarily make it hotter beyond this point. Furthermore, molecular vibrational energy influences how quickly a system reaches saturation, impacting heat transfer rates. Additionally, thermal conductivity impacts how rapidly heat can be distributed within a material, affecting the saturation process.

Why Doesn’t Preheating Guarantee the Highest Temperature?

Preheating alone doesn’t make sure you’ll reach the highest temperature because heat transfer is limited by material properties and insulation. Even if you start at a higher temperature, it takes time for the system to reach thermal equilibrium. Understanding these factors helps explain why preheating isn’t always enough to achieve maximum heat. Additionally, the efficiency of a heat pump can be affected by system design, which influences how effectively heat is transferred and maintained. Proper insulation and system performance optimization are crucial for maximizing temperature levels efficiently.

Heat Transfer Limitations

Even if you preheat a material, it doesn’t automatically mean you’ll reach the highest possible temperature. Heat transfer limitations play a big role in this. Factors like phase change can absorb significant energy without raising temperature, creating a barrier to reaching maximum heat. Similarly, the material’s heat capacity determines how much energy it can store before heating up further. Insufficient heat transfer methods or poor contact can slow down the process, preventing the material from reaching its true thermal potential. Additionally, high contrast ratios in imaging systems demonstrate how effective heat transfer is essential for achieving clarity and depth in visuals. Understanding heat transfer efficiency is crucial for optimizing thermal processes and ensuring that preheating achieves its full potential. Proper filtration can also influence heat transfer by maintaining the cleanliness of equipment and preventing clogging that impedes heat flow.

Material Insulation Effects

Have you ever wondered why heating a material doesn’t always lead to the highest possible temperature? It comes down to material properties and insulation effects. Different materials have unique thermal conductivities, heat capacities, and surface properties that influence how heat is absorbed and retained. Insulation effects play a vital role; some materials trap heat effectively, while others allow rapid heat loss. Even if you preheat a material, poor insulation can prevent it from reaching the maximum temperature you expect. Conversely, high-quality insulation minimizes heat loss, but material properties still limit how hot the material can get before reaching saturation. Understanding these effects helps explain why preheating alone doesn’t guarantee the highest temperature—material characteristics and insulation effects set the ultimate thermal limits.

Time to Reach Equilibrium

While preheating can raise a material’s temperature quickly, it doesn’t mean the system will reach thermal equilibrium instantly. Achieving equilibrium depends on how heat moves within the object, influenced by factors like heat capacity and temperature gradient. Your material needs time for heat to distribute evenly, balancing internal and external temperatures.

- The heat capacity determines how much energy is needed for temperature change

- A steep temperature gradient slows heat transfer, delaying equilibrium

- Heat flows from hot to cold regions until temperatures stabilize

- Larger or thicker objects take longer to reach uniform temperature

- Preheating only raises initial temperature; full equilibrium takes additional time

Understanding these factors explains why preheating alone doesn’t guarantee the highest, most uniform temperature immediately.

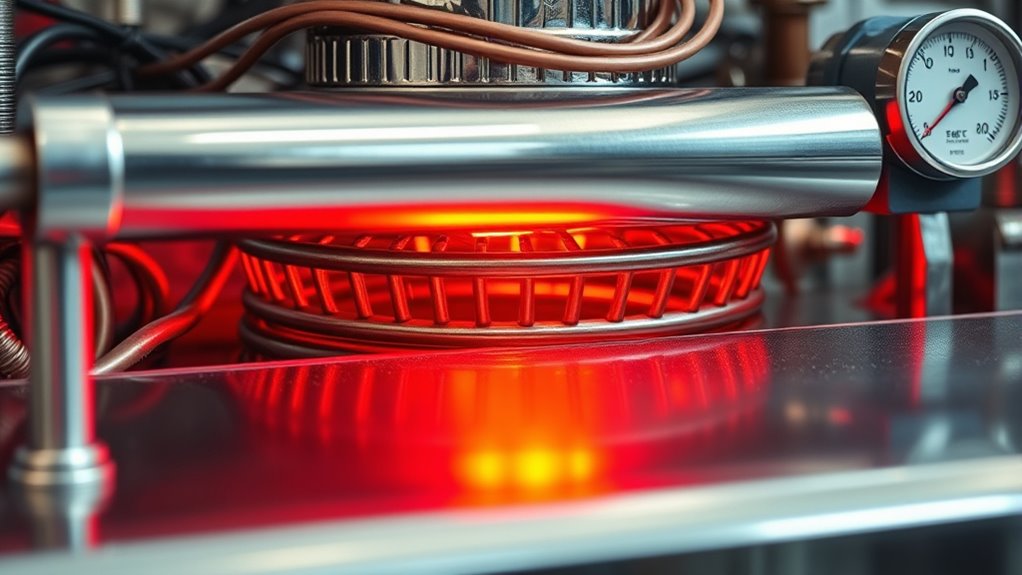

What Causes Thermal Saturation in Heating Systems?

Thermal saturation in heating systems occurs when the temperature of the heating medium reaches a point where it can no longer absorb additional heat effectively. This happens because the material’s thermal conductivity decreases as temperature rises, limiting heat transfer efficiency. Additionally, the heat capacity of the medium influences how much energy it can store; once it nears its maximum, extra heat doesn’t raise the temperature further. If your system’s components, like pipes or fluids, have a high heat capacity, they can become saturated quickly, preventing further temperature increases. As a result, the system struggles to reach higher temperatures, causing preheating to plateau. Recognizing thermal properties and their impact on your system can help you identify why your heating system hits a thermal ceiling prematurely. Understanding these factors helps you identify why your heating system hits a thermal ceiling prematurely. Recognizing free floating conditions in your system can also contribute to inefficient heat transfer and saturation issues.

How Can You Spot Signs of Thermal Saturation in Your Setup?

Recognizing the signs of thermal saturation early can save you time and prevent system inefficiencies. Use thermal imaging to detect hotspots that indicate excess heat buildup, which standard sensors might miss. Check your temperature sensors regularly for inconsistent readings or sudden fluctuations, signaling saturation. Look for uneven heating patterns on equipment surfaces or piping, which suggest thermal imbalance. Notice if your system requires more energy to reach desired temperatures, a sign it’s working harder due to saturation. Additionally, monitor for increased system noise or vibrations, often caused by thermal stress. Regular inspections with thermal imaging and calibrated temperature sensors will help you catch these signs early, allowing you to take corrective action before performance degrades. Understanding thermal management is key to maintaining optimal system efficiency and longevity. Being aware of heat dissipation techniques can also help prevent saturation from occurring in the first place. Incorporating thermal monitoring practices into your routine will further enhance early detection capabilities. Implementing smart sensors that provide real-time data can improve your ability to respond promptly to signs of saturation.

How Can You Overcome Thermal Saturation for Better Heating?

To improve your heating performance, focus on enhancing heat transfer efficiency and optimizing your system design. Simple adjustments can help you guarantee thermal saturation and achieve better, more consistent warmth. By making strategic changes, you can assure your setup heats effectively without unnecessary energy loss. Understanding water chemistry is also essential to prevent issues like scaling or corrosion that can impair heat transfer efficiency. Additionally, ensuring proper ventilation can help maintain optimal operating temperatures and system longevity.

Enhance Heat Transfer Efficiency

Overcoming thermal saturation is essential for enhancing heat transfer efficiency, especially when you want to achieve faster and more uniform heating. To improve heat transfer, focus on increasing thermal conductivity to allow heat to move more quickly through materials. Reducing heat capacity helps materials warm up faster, minimizing delays caused by stored thermal energy. You can also optimize contact between surfaces to reduce thermal resistance. Applying agitation or stirring promotes better heat distribution. Using high-quality insulation ensures minimal heat loss, maintaining consistent temperatures. Additionally, employing advanced heating techniques like induction or microwave heating can bypass saturation limits, delivering energy directly to the target areas more effectively. Incorporating thermal management techniques such as heat conduction, which improves the transfer of heat between surfaces, can significantly enhance efficiency. Furthermore, understanding the role of thermal diffusivity in heat transfer processes helps in selecting appropriate materials for faster heating. Additionally, incorporating elements like electric dirt bikes with high horsepower can demonstrate rapid power application, analogous to improving heat transfer efficiency. These strategies help you overcome thermal saturation, ensuring faster, more efficient heating.

Optimize Heating System Design

Designing an effective heating system requires careful consideration of how thermal saturation can limit performance. To overcome this, optimize your system by accounting for thermal expansion, which can cause components to shift or crack if not managed properly. Improve heat diffusion by ensuring even heat distribution throughout the space, preventing localized saturation zones. Use materials with high thermal conductivity to facilitate efficient heat transfer and minimize hotspots. Incorporate advanced controls that adjust heating based on real-time temperature feedback, avoiding excessive preheating that leads to saturation. Proper insulation also plays a critical role, reducing heat loss and maintaining consistent temperatures. Additionally, understanding the regulatory environment can help ensure compliance and optimize system design within legal frameworks. Considering thermal management techniques can further enhance the system’s performance and longevity. Employing thermal sensors can provide precise data to optimize operation and prevent overheating issues. By fine-tuning these elements, you enhance overall efficiency, prevent thermal saturation from hampering performance, and ensure that your heating system delivers sustained, effective warmth. Implementing proper maintenance practices can also extend the lifespan of the system and prevent unexpected saturation problems.

Why Do Material Choices and System Design Matter?

Material choices and system design are crucial because they directly influence how efficiently heat is transferred and retained within a system. Your selection of materials affects key properties like thermal conductivity, determining how quickly heat moves through components. Using high thermal conductivity materials, like copper, ensures rapid heat transfer, while insulators slow it down to conserve energy. Design choices, such as insulation placement and surface area, also impact overall performance. Consider these factors:

- Material properties like thermal conductivity and heat capacity

- Proper insulation to minimize heat loss

- Surface area optimization for better heat transfer

- Compatibility of materials to prevent degradation

- System layout that promotes efficient flow

- Material properties like thermal conductivity and heat capacity directly influence how effectively heat is transferred and retained

Choosing the right materials and designing thoughtfully helps maximize heat retention, reduce energy waste, and achieve ideal system efficiency.

How to Keep Your Heating System Performing at Its Best

To keep your heating system performing at its best, regular maintenance and timely inspections are essential. Ensuring ideal thermal conductivity allows heat to move efficiently, preventing hotspots and overheating. Properly cleaned components improve heat dissipation, reducing energy waste and prolonging system life. Visualize your system as a grid:

| Component | Function | Maintenance Tip |

|---|---|---|

| Heat Exchanger | Transfers heat to air | Clear debris regularly |

| Thermostat | Regulates temperature | Calibrate annually |

| Ventilation | Disperses heat evenly | Check for blockages |

| Insulation | Minimizes heat loss | Inspect for damage |

| Fans | Circulate warm air | Lubricate moving parts |

Frequently Asked Questions

How Does Thermal Saturation Differ From Other Heat Transfer Limitations?

Thermal saturation differs from other heat transfer limitations because it occurs when a material reaches its maximum heat transfer efficiency, dictated by its thermal capacity. You’ll find that, despite preheating, the material can’t absorb or transfer more heat efficiently once saturation is reached. This limits further temperature increases, making it essential to contemplate material properties and thermal capacity to optimize heating processes and avoid unnecessary energy use.

Can Thermal Saturation Occur in All Heating Systems?

Yes, thermal saturation can occur in all heating systems. When your system reaches saturation thresholds, heat transfer efficiency drops because the medium can’t absorb or transfer more heat effectively. This limits how hot your system gets, regardless of how much you preheat. To avoid this, you need to monitor saturation levels and optimize operating conditions, ensuring your system maintains maximum efficiency without hitting those critical saturation points.

What Temperature Levels Are Considered Optimal Before Saturation?

You should aim for temperature thresholds that stay below the saturation points specific to your system, typically around 200°F to 212°F for water-based systems. Staying within these limits ensures efficient heat transfer without risking thermal saturation. If you exceed these levels, you risk system inefficiencies or damage. Always monitor your temperature gauges closely, and adjust your preheating process to keep temperatures ideal and avoid reaching saturation.

Are There Specific Materials More Prone to Thermal Saturation?

Certain materials are more prone to thermal saturation due to their properties, such as high thermal conductivity and specific heat capacity. Metals like copper and aluminum tend to saturate quicker because they absorb and transfer heat efficiently, showing strong saturation tendencies. Conversely, insulators like ceramics resist saturation longer. Your understanding of material properties helps you predict saturation risks and optimize heating processes for different materials effectively.

How Often Should System Maintenance Be Performed to Prevent Saturation Effects?

Think of your system as a garden that needs regular watering to thrive. To prevent saturation effects, you should perform maintenance frequently—ideally every 3 to 6 months. This maintenance frequency keeps thermal saturation at bay and guarantees peak performance. Regular checks and adjustments are key for saturation prevention, helping your system run smoothly and avoiding costly issues down the line. Don’t wait—stay proactive for the best results.

Conclusion

Understanding thermal saturation helps you realize that preheating alone won’t always get your system to maximum temperature. By recognizing the signs and optimizing your setup, you can prevent hitting a wall. Remember, you can’t have your cake and eat it too—sometimes, you need to adjust your approach rather than rely solely on preheating. Keep an eye on your system’s performance, and don’t be afraid to tweak things for the best results.