If you’re looking for the best continuous band sealers for bakery packaging in 2026, I’ve found several top models that offer adjustable temperatures, high sealing speeds up to 52.5 ft/min, and versatile sealing widths. Many include features like built-in printing for dates and logos, durable construction, and safety options. These machines are perfect for small bakeries and food packagers aiming for efficiency and quality. Keep exploring to discover which model suits your needs best.

Key Takeaways

- Highlights top-rated continuous band sealers suitable for bakery packaging in 2026, emphasizing efficiency, versatility, and durability.

- Details key features like adjustable temperature, sealing speed, width, and compatibility with various packaging materials.

- Includes information on printing options, accessories, and safety features for high-volume bakery operations.

- Offers insights into user benefits such as consistent seals, customization, and ease of maintenance.

- Guides on selecting sealers based on bakery needs, material compatibility, and optimal settings for quality packaging.

VEVOR Continuous Band Sealer with Digital Control

The VEVOR Continuous Band Sealer with Digital Control is an excellent choice for small bakeries and home-based packaging needs because it combines adjustable heat settings with a fast sealing speed. I appreciate its versatile 0.32–0.47-inch adjustable seal width, perfect for plastic, kraft paper, and foil bags. Operating at up to 29.5 feet per minute, it boosts efficiency without sacrificing quality. Its 400W power allows precise temperature control from 122°F to 482°F, making sealing straightforward. The compact design and safety features, like automatic shutdown and a covered heating zone, make it easy and safe to use, streamlining your packaging process.

Best For: small bakeries, home-based packagers, and small businesses seeking efficient, adjustable sealing for plastic, kraft paper, and foil bags.

Pros:

- Adjustable seal width (0.32–0.47 inches) for versatile bag sealing

- Fast sealing speed up to 29.5 feet per minute for increased efficiency

- Safe operation with automatic shutdown and covered heating zone

Cons:

- May require some initial calibration to perfect temperature settings

- Limited to small-scale sealing tasks, not suitable for large industrial needs

- Plastic and foil compatibility may vary depending on bag thickness and material

VEVOR Continuous Bag Sealer with Ink Printing

If you’re looking for a reliable sealer that combines continuous operation with versatile printing options, the VEVOR Continuous Bag Sealer with Ink Printing stands out. It features an adjustable seal width from 0.24 to 0.47 inches, powered by a 600W motor that seals up to 52.5 feet per minute. This machine is perfect for sealing thin plastic bags, from 0.001 to 0.03 inches thick, with temperature control from 32°F to 572°F. Its printing capabilities let you add text, dates, logos, barcodes, and QR codes via manual input or USB files, making packaging both efficient and customizable.

Best For: small to medium-sized businesses, bakeries, warehouses, and workshops seeking efficient, customizable sealing and printing solutions for plastic bags.

Pros:

- Adjustable seal width (0.24 to 0.47 inches) for versatile bag sizes

- High sealing speed of up to 52.5 ft/min increases productivity

- Multiple printing options for adding text, logos, barcodes, and QR codes

Cons:

- Ink for printing requires a separate purchase (Model: HP 2590 W3T10)

- Limited to sealing plastic bags with thickness up to 0.03 inches

- Manual setup may require some initial adjustment for optimal performance

Commercial Heat Sealer Machine with Digital Temperature Control

A commercial heat sealer machine with digital temperature control stands out as the ideal choice for professionals who need precise, consistent seals in high-volume bakery packaging. Its adjustable digital temperature (0-300°C) and speed control (up to 12 m/min) let you customize each seal for superior quality and efficiency. Built with durable steel and corrosion-resistant materials, it guarantees reliable, long-lasting operation. The compact design makes it easy to move around your workspace. Plus, safety features like a discharge support plate, along with extensive accessories, help reduce downtime and maintenance costs. Overall, this machine offers precise control, durability, and versatility for busy bakery operations.

Best For: professional bakers, food packagers, and food storage facilities requiring precise, high-volume sealing with reliable performance.

Pros:

- Precise digital temperature control (0-300°C) for consistent, airtight seals

- Adjustable speed up to 12 m/min enhances workflow efficiency

- Durable steel construction with corrosion-resistant materials ensures long-term reliability

Cons:

- May have a higher initial cost compared to basic sealing models

- Requires some training to optimize temperature and speed settings effectively

- Compact size might limit sealing width for very large bags

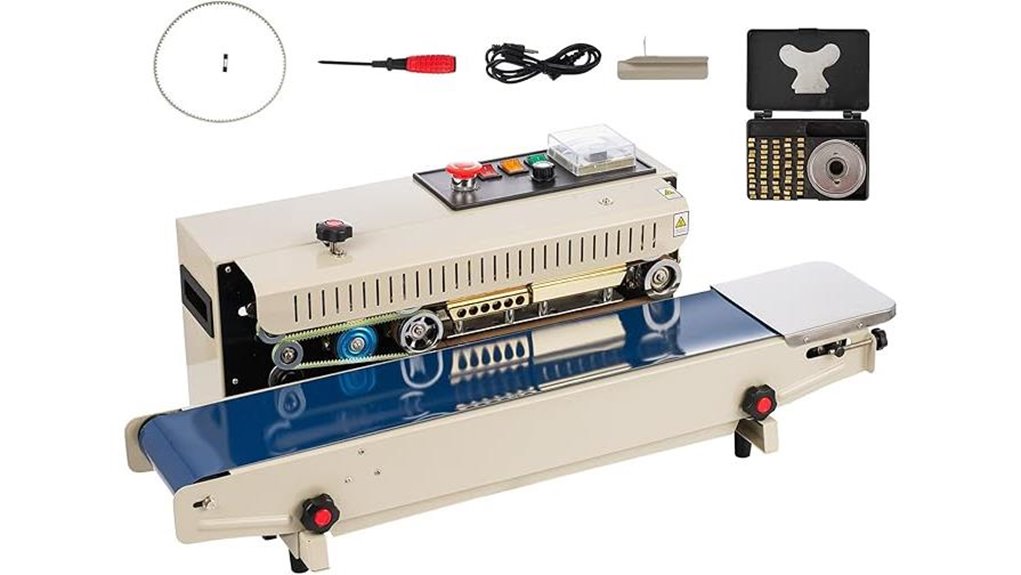

VEVOR Continuous Bag Sealer with Printing Function

Vevor’s FR900K continuous band sealer stands out for its built-in printing function, making it ideal for bakery businesses that need to personalize packaging on the fly. Its all-metal construction and durable iron body guarantee long-lasting performance, while the powerful DC copper motor provides reliable operation. The sealer can handle various materials like plastic, foil, and paper bags up to 0.8 mm thick, with adjustable speed and temperature for precise sealing. The integrated embossing and type wheels allow me to print dates, logos, and remarks simultaneously, streamlining my packaging process. Overall, this machine offers efficiency and customization perfect for bakery needs.

Best For: bakery businesses and food packaging operations seeking efficient, customizable sealing with on-the-fly printing capabilities.

Pros:

- Durable all-metal construction ensuring long-lasting performance

- Built-in embossing and type wheels for simultaneous printing of dates, logos, and remarks

- Adjustable speed, temperature, and sealing parameters for precise customization

Cons:

- May require training for optimal use of printing and sealing features

- Limited to materials up to 0.8 mm thickness, not suitable for very thick bags

- Initial setup and calibration can be time-consuming for new users

VEVOR Continuous Bag Sealer with Adjustable Temperature

Designed for versatility and efficiency, the VEVOR Continuous Bag Sealer with Adjustable Temperature is an excellent choice for bakeries needing reliable, high-speed packaging. Its powerful 600W motor seals up to 52.5 ft/min, making quick work of large batches. You can adjust the sealing width from 0.24 to 0.47 inches and set the temperature from 32℉ to 572℉, accommodating various bag types and thicknesses. Features like a built-in counter, roller printing, and easy setup streamline operations. Its sturdy construction and user-friendly design guarantee consistent, quality seals, helping bakeries boost productivity while maintaining packaging flexibility.

Best For: bakeries and small workshops seeking high-speed, reliable plastic bag sealing with adjustable settings and versatile bag compatibility.

Pros:

- Powerful 600W motor with sealing speeds up to 52.5 ft/min for efficient operation

- Adjustable temperature (32℉ to 572℉) and sealing width (0.24 to 0.47 inches) for versatility

- Includes useful features like a built-in counter and roller printing for batch tracking and date marking

Cons:

- Weighs 28 pounds, which may require some effort to move or reposition

- Limited to plastic bags with thicknesses between 0.001 to 0.03 inches, not suitable for thicker materials

- Customer rating of 4.2 stars based on a small number of reviews, indicating potential variability in user satisfaction

Commercial Automatic Bag Sealer with Digital Temp Control

The Commercial Automatic Bag Sealer with Digital Temp Control stands out for its precise temperature adjustments, making it ideal for bakery professionals who need consistent and reliable seals. Its digital thermostat allows easy setting of temperatures up to 300°C, ensuring perfect seals on various materials like plastic, foil, and paper. With a high-speed motor reaching 16 meters per minute and adjustable sealing width from 6mm to 12mm, it maximizes efficiency and versatility. The desktop design, sturdy metal construction, and smooth 6-inch conveyor belt make operation straightforward. Plus, responsive customer support and warranty options add confidence, making this sealer a top choice for busy bakery packaging.

Best For: bakery professionals and small to medium-sized food packaging businesses seeking precise, efficient, and versatile bag sealing solutions.

Pros:

- Digital temperature control allows for precise and consistent seals across various materials.

- High-speed sealing capacity of up to 16 meters per minute boosts packaging efficiency.

- Adjustable sealing width (6mm-12mm) and compatibility with different bag types enhance versatility.

Cons:

- Limited to bags with thicknesses between 0.02mm-0.16mm, which may not suit all packaging needs.

- Requires a power source of 110V/60Hz, limiting use in regions with different electrical standards.

- Desktop design may not be suitable for high-volume industrial applications requiring larger or more robust equipment.

Commercial Heat Sealer Machine with Adjustable Settings

A commercial heat sealer machine with adjustable settings is an excellent choice for bakery packaging operations that require flexibility and precision. I find that its adjustable speed (0-12 m/min) and temperature (0-300°C) let me customize sealing for different materials, like foil, kraft paper, or CPP bags. The sealing width, adjustable between 6-12mm, accommodates various bag sizes. With a powerful 600W heating element, it heats up quickly, boosting productivity. The user-friendly controls make it easy to fine-tune settings, ensuring consistent, high-quality seals. This versatility makes the machine ideal for both industrial and kitchen use, optimizing workflow and sealing reliability.

Best For: bakery packaging operations and food producers seeking a versatile, adjustable sealing solution for various bag materials and sizes.

Pros:

- Adjustable speed and temperature for customizable sealing on different materials

- Rapid 600W heating for quick and efficient sealing, increasing productivity

- User-friendly controls that ensure consistent, high-quality seals

Cons:

- Internal structure causes displayed temperature to be lower than actual, requiring adjustments during use

- Sealing width is adjustable only between 6-12mm, which may not suit very small or very large bags

- May require consultation for sealing certain unfamiliar materials to ensure optimal performance

Vertical Continuous Sealing Machine with Digital Temp Control

If you’re looking for a reliable solution to accelerate your bakery packaging, a vertical continuous sealing machine with digital temperature control is an excellent choice. It offers high-speed operation, sealing up to 12 meters per minute, perfect for large volumes. The machine handles various bag sizes and materials, including plastic and laminated films, with a sealing width of up to 0.47 inches. Its digital temperature control guarantees precise and consistent seals, operating from 0 to 300°C. Compact and durable, it’s designed for continuous use in demanding environments, and the built-in counter boosts efficiency by tracking sealed packages, streamlining your workflow.

Best For: businesses in the food, pharmaceutical, or chemical industries seeking high-speed, precise, and durable packaging solutions for large-volume production.

Pros:

- Supports sealing speeds up to 12 meters per minute, ensuring rapid packaging.

- Digital temperature control provides precise and consistent sealing across various materials.

- Compact and durable design ideal for limited spaces and continuous, demanding use.

Cons:

- Sealing width is limited to a maximum of 0.47 inches, which may not suit larger bag sizes.

- Operating temperature range up to 300°C may require careful monitoring to avoid overheating.

- Load capacity is limited to 5 kg, potentially restricting the size or weight of packages.

VEVOR Horizontal Bag Sealer with Digital Temperature Control

For bakers and food packagers seeking precise control, the VEVOR Horizontal Bag Sealer with Digital Temperature Control stands out thanks to its adjustable sealing width and digital temperature settings. It supports bags from 0.02 to 0.8 mm thick with a sealing width of 0.24 to 0.47 inches. Built from durable carbon steel, it offers fast, stable sealing with a powerful 600W motor, supporting speeds up to 52.49 ft/min. The digital controls and automatic operation make it easy to use, while features like embossing and alphanumeric printing add customization options. Its reliable performance and user-friendly design make it a versatile choice for bakery packaging needs.

Best For: bakers, food packagers, and small-scale manufacturers seeking precise, efficient, and customizable sealing solutions.

Pros:

- Adjustable sealing width and digital temperature control for precise customization

- Supports a wide range of bag thicknesses (0.02-0.8mm) and fast sealing speeds up to 52.49 ft/min

- Durable construction with easy-to-use digital interface and multiple printing options

Cons:

- Heavier weight (21.7 pounds) may require stable setup space

- Power requirements of 220V may limit portability in some regions

- Limited to specific bag thicknesses and widths, which may not suit all packaging needs

Egofoy 50pcs PTFE Tape for Band Sealer Machines

Egofoy’s 50pcs PTFE Tape stands out as an essential accessory for bakery operators using the FR-900 Continuous Band Sealer, thanks to its seamless construction and high durability. Made from high-strength PTFE Teflon, these belts measure 29.5 inches long and 0.59 inches wide, with a thickness of 0.008 inches. They resist extreme temperatures from -60°C to 260°C and are highly resistant to acids, alkali, and organic solvents. The belts’ seamless design ensures smooth operation, reduces machine wear, and prevents biasing. Easy to clean and maintain, these belts enhance sealing efficiency and longevity, making them a reliable choice for continuous bakery packaging.

Best For: bakery operators and industrial sealing professionals seeking durable, seamless PTFE belts for continuous band sealing machines like the FR-900.

Pros:

- Seamless construction provides smooth operation and reduces biasing.

- High resistance to extreme temperatures, acids, alkali, and organic solvents ensures long-lasting performance.

- Easy to clean, maintain, and resistant to adhesives, enhancing sealing efficiency and reducing downtime.

Cons:

- Length and width may require customization for non-standard sealing machines.

- The belts’ flexibility could be limited due to high-strength PTFE material.

- Slightly higher cost compared to traditional jointed belts, though justified by durability.

Continuous Band Sealer FR900K for Plastic Bags

The Continuous Band Sealer FR900K stands out as an ideal choice for high-volume bakery operations that require fast, reliable sealing. Designed for commercial use, it seals plastic, aluminum foil, paper, and compound bags efficiently at speeds up to 16 meters per minute. Its adjustable sealing width and thermostatic temperature control allow for precise customization, ensuring consistent results across various materials. Built with a durable iron body, stainless steel components, and a high-efficiency DC copper motor, it’s designed for durability and continuous performance. Plus, its advanced printing features make it easy to add dates or logos during sealing, streamlining branding and traceability.

Best For: high-volume bakery operations and commercial packaging facilities requiring fast, reliable sealing with customizable settings and branding capabilities.

Pros:

- High-speed sealing up to 16 meters per minute for efficient production

- Adjustable sealing width and thermostatic temperature control for versatile use

- Built-in advanced printing features for adding dates, logos, or remarks during sealing

Cons:

- May be heavy and require sufficient workspace due to durable construction

- Initial setup and calibration might take time for optimal performance

- Cost may be higher compared to smaller or manual sealers, depending on the application

Continuous Band Bag Sealer with Inkjet Printing

A continuous band bag sealer with inkjet printing stands out as an ideal choice for businesses seeking efficient, high-quality packaging solutions. Its 750W pure copper motor guarantees stable, rapid operation, perfect for sealing bags up to 0.08 mm thick and 14 mm wide. The adjustable control panel allows precise temperature and speed settings, while the conveyor height adapts for various item sizes. The integrated inkjet printer produces clear text, QR codes, and graphics, meeting diverse labeling needs. Built with durable materials and equipped with ventilation holes, this sealer is suitable for food, pharmaceutical, and industrial packaging, offering reliability and versatility in a single machine.

Best For: businesses in food processing, pharmaceuticals, chemicals, and agriculture seeking efficient, high-quality, versatile packaging solutions.

Pros:

- High-power 750W copper motor ensures stable and rapid sealing performance.

- Adjustable temperature, speed, and conveyor height for customized operation.

- Integrated inkjet printing produces clear, versatile text, QR codes, and graphics.

Cons:

- May require training for optimal adjustment of temperature and speed settings.

- Limited to bag thickness up to 0.08 mm, restricting some heavy-duty applications.

- The machine’s size and setup might be less suitable for very small or highly space-constrained workplaces.

Phezer Automatic Plastic Bag Sealer with Digital Temp

For those seeking precise control and reliable sealing performance, the Phezer Automatic Plastic Bag Sealer with Digital Temp stands out as an ideal choice. Its advanced sealing structure with a digital temperature control panel ensures consistent, high-quality seals on various plastic and poly bags. The roller heat sealer features a 28W motor, sealing at 7 meters per minute with a 0.39-inch width, compatible with materials like LDPE, HDPE, PP, aluminum foil, and kraft paper. Safety is prioritized with auto cooling and shutdown functions. Its durable all-metal build, lightweight design, and optional conveyor attachment make it perfect for both household and industrial use.

Best For: home users, small businesses, and industrial facilities seeking precise, reliable, and efficient plastic bag sealing solutions.

Pros:

- Digital temperature control ensures consistent and high-quality seals.

- Durable all-metal construction and powerful DC copper motor for long-lasting performance.

- Portable and lightweight design with optional conveyor attachment for increased flexibility and efficiency.

Cons:

- Sealing width limited to 0.39 inches, which may not suit larger bags.

- Requires electricity, so outdoor or remote use may be limited without power sources.

- The all-metal construction, while durable, might be heavier compared to plastic-bodied sealers.

Automatic Bag Sealing Machine with Digital Temp Control

An automatic bag sealing machine with digital temperature control stands out as an ideal choice for small bakeries and home-based businesses seeking efficient, consistent packaging. The ZHONGMIN FRC-510 offers high-speed sealing up to 16 meters per minute, boosting productivity. Its adjustable seal width (6-12mm) works with various plastic bags, films, and pouches. The machine heats quickly and maintains a steady temperature up to 300°C, ensuring reliable seals on materials from 0.02 to 0.16 mm thick, including foil and paper. Compact and easy to operate, it’s perfect for continuous sealing tasks, making packaging faster, easier, and more professional.

Best For: small bakeries, home-based businesses, and packaging operations requiring efficient, reliable sealing of plastic, foil, and paper bags.

Pros:

- High-speed sealing up to 16 meters per minute enhances workflow efficiency.

- Digital temperature control allows precise adjustment for various materials.

- Compact design and adjustable seal width (6-12mm) ensure versatility and ease of use.

Cons:

- Limited to sealing bags with thickness between 0.02 mm and 0.16 mm, which may not suit heavy-duty packaging.

- Requires an AC power source (110V/60Hz), limiting portability in some locations.

- May have a learning curve for users unfamiliar with digital controls and adjustable settings.

Continuous Band Bag Sealer with Adjustable Settings

The SHZOND FR900 Continuous Band Sealer stands out for its precise adjustable settings, making it ideal for operators who need customizable sealing parameters. With adjustable temperature from 32°F to 572°F and sealing speed up to 52.5 ft/min, I can tailor the process to different bag materials and thicknesses. The sealing width is adjustable between 0.24-0.59 inches, and pressure can be fine-tuned for excellent results. Its electronic thermostat control and intelligent features ensure consistent performance. This versatility helps me achieve reliable, high-quality seals across various industries, from baked goods to pharmaceuticals, all while maintaining efficient, hassle-free operation.

Best For: businesses and operators seeking a customizable, high-efficiency continuous band sealer for various plastic and composite bags across industries like food, pharmaceuticals, and chemicals.

Pros:

- Precise adjustable temperature, speed, and pressure for versatile sealing options

- Automatic operation with intelligent controls ensures consistent, high-quality seals

- Suitable for a wide range of bag materials and thicknesses, enhancing productivity

Cons:

- Slightly heavy at approximately 36.8 pounds, which may require stable setup space

- May require initial calibration to optimize for specific bag types and thicknesses

- Limited to bags within the specified thickness range of 0.02mm to 0.8mm

Factors to Consider When Choosing a Continuous Band Sealer for Bakery Packaging

When selecting a continuous band sealer for bakery packaging, I consider factors like sealing width flexibility and temperature control precision to guarantee consistent results. Speed efficiency and material compatibility are also vital to match production needs and packaging varieties. Finally, safety features and ease of maintenance help keep operations smooth and safe over time.

Sealing Width Flexibility

Sealing width flexibility is a crucial factor to consider when selecting a continuous band sealer for bakery packaging because it directly affects the machine’s ability to handle various bag sizes and materials. I look for models with an adjustable sealing width range of at least 0.24 to 0.47 inches, ensuring versatility across different bakery products. The ability to easily modify the sealing width, whether through adjusting stopper depth or control panel settings, allows quick adaptation to different packaging requirements. A wider sealing width improves sealing quality for larger or thicker bakery bags, reducing leaks and spoilage risks. Flexible sealing width options also enable seamless handling of everything from small pastry bags to large bread packaging, making the machine more adaptable to my production needs.

Temperature Control Precision

Achieving precise temperature control is vital for consistent sealing quality in bakery packaging, as fluctuations can lead to under- or over-sealed bags that compromise product freshness. Digital temperature settings allow for fine adjustments, typically within 32°F to 572°F, making it easy to match different bag materials. Accurate regulation helps prevent overheating or burning, reducing material waste and ensuring a clean seal. Reliable systems often include automatic shutoff features that activate once optimal heat levels are reached, enhancing safety and efficiency. Maintaining stable temperatures throughout the sealing process is fundamental for preserving the integrity and freshness of bakery products. When selecting a sealer, look for models with adjustable, precise temperature controls to guarantee consistent, high-quality seals every time.

Sealing Speed Efficiency

Choosing the right sealing speed is essential for maximizing efficiency without sacrificing quality in bakery packaging. A higher speed, like 52.5 ft/min, can dramatically boost throughput, reducing production time per batch. This allows me to meet higher demand and improve overall productivity. However, I always ensure the sealing speed is adjustable, so I can customize it based on different bag sizes and material thicknesses for the best results. It’s imperative to balance speed with heat control because rushing the process can cause uneven seals or damage delicate bakery items. Consistent sealing speed is key to maintaining uniformity and quality across all packages. When selecting a sealer, I look for one that offers high efficiency without compromising the integrity of the seal or the safety of the product.

Material Compatibility Range

When selecting a continuous band sealer for bakery packaging, ensuring material compatibility is vital for achieving reliable seals and maintaining product quality. I look for a sealer that can handle various bag materials like plastic, kraft paper, aluminum foil, and composite films, depending on my needs. Checking the maximum sealing thickness supported, usually between 0.02 mm and 0.8 mm, helps guarantee secure sealing for different bag types. I also verify the adjustable sealing width and temperature settings to optimize adhesion for each material. Supporting both heat-sensitive and heat-resistant materials is essential to prevent damage or weak seals. Finally, I confirm the machine’s compatibility with food-grade, FDA-approved, or food-safe materials, especially when sealing products in direct contact with edible goods.

Safety and Maintenance Features

Safety and maintenance features are critical considerations to guarantee reliable and secure operation of a continuous band sealer in bakery packaging. I look for models with automatic shutdowns at temperatures like 122°F to prevent overheating and minimize hazards. Protective design elements, such as covered heating zones and discharge support plates, keep operators safe by reducing contact with hot surfaces. Maintenance-friendly features, like PTFE-coated conveyor belts and quick-access parts, help lower downtime and make cleaning easier. Durable construction from corrosion-resistant materials extends the machine’s lifespan and reduces safety risks caused by wear. Additionally, features like backup fuses and modular components simplify repairs and routine maintenance, ensuring the sealer stays safe and reliable over time. These features are essential for smooth bakery packaging operations.

Frequently Asked Questions

How Do I Maintain Consistent Seal Quality During High-Volume Bakery Production?

To maintain consistent seal quality during high-volume bakery production, I regularly clean and calibrate my sealer to prevent any debris or misalignments. I also monitor the temperature settings closely, ensuring they stay within ideal ranges. Using high-quality sealing materials and conducting routine quality checks helps me catch issues early. Staying attentive and consistent with maintenance makes a big difference in achieving reliable, professional seals every time.

What Safety Features Are Essential in Commercial Continuous Band Sealers?

You might worry about safety features in commercial sealers, but they’re essential for your peace of mind. I always look for automatic shut-off systems, emergency stop buttons, and safety guards that prevent accidental contact with moving parts. These features safeguard my staff and ensure smooth operation. Investing in sealers with these safety measures means fewer accidents and more efficient production, making safety a top priority in my bakery.

Can These Sealers Handle Different Bakery Product Packaging Materials Effectively?

Absolutely, these sealers can handle a variety of bakery packaging materials effectively. I’ve used them with different films, foils, and laminated materials, and they consistently deliver a tight, secure seal. Their adjustable temperature controls and versatile sealing settings make it easy to customize for each product type. Whether packaging bread, pastries, or cookies, I find these sealers reliable and efficient, ensuring freshness and quality every time.

How Energy-Efficient Are the Latest Continuous Band Sealer Models?

Imagine a sealer that sips energy like a gentle breeze rather than a roaring storm—that’s what the latest models do. They’re incredibly energy-efficient, using advanced insulation and smart technology to minimize power use while maximizing performance. I’ve seen them operate seamlessly, cutting energy costs and reducing environmental impact. These sealers are like a well-tuned engine, delivering power precisely when needed without wasting a drop of fuel.

Are There Eco-Friendly Options Available for Bakery Packaging Sealers?

Yes, eco-friendly options are available for bakery packaging sealers. I’ve found models that use energy-efficient motors and biodegradable materials, reducing environmental impact. Many brands now prioritize sustainability, offering sealers with lower power consumption and recyclable components. Switching to these options not only helps the environment but also appeals to eco-conscious consumers. I recommend researching brands committed to green technology to find a sealer that aligns with your sustainability goals.

Conclusion

Choosing the right continuous band sealer is like finding a trusted companion for your bakery’s success. With so many options, it’s about matching features to your needs and trusting your instincts. Remember, a great sealer isn’t just a machine—it’s the silent partner sealing in freshness and flavor. So, pick wisely, and let your bakery’s reputation rise as steadily as your perfectly sealed treats!