I’ve looked into the 15 best twist tie machines for bread bags in 2026, and I can tell you there are many great options. These machines are designed to boost productivity, with features like automatic operation, adjustable tension, and fast tying speeds. They’re perfect for bakeries, grocery stores, or retail environments looking for reliable sealing solutions. Keep exploring to discover which models fit your specific needs and how to get the best results.

Key Takeaways

- The top twist tie machines support bag diameters from 0.1 to 1.2mm for versatile bread bag sealing.

- High-speed models can tie up to 40 ties per second, boosting bakery and retail productivity.

- Fully automatic, sensor-activated machines ensure hands-free operation and consistent closures.

- Durable, food-safe construction with adjustable tension, tie length, and speed for various packaging needs.

- Key factors include compatibility, tying speed, ease of use, build quality, and regional power standards.

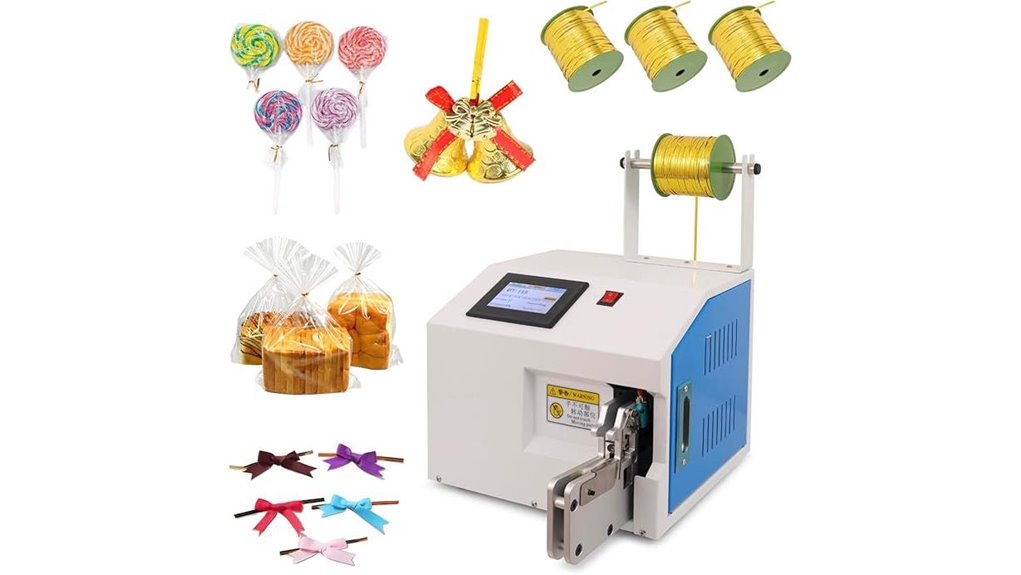

Automatic Twist Tie Sealing & Bundling Machine

If you’re looking for a reliable machine to streamline your packaging process, the Automatic Twist Tie Sealing & Bundling Machine is an excellent choice. It features gold wire sealing capabilities and comes with five durable wire rolls, with more available if needed. The machine boasts five key upgrades, including an inductive bag tying port that seals in just one second, a high-definition LCD screen with bilingual support, and an adjustable stainless steel reel. Its microcontroller and stepper motor guarantee precise operation, handling bundling diameters from 0.19 to 1.18 inches at speeds up to 75 ties per minute. It’s perfect for efficiently managing cables, wires, and other small items.

Best For: businesses and industries requiring efficient, high-speed cable bundling and wire management solutions.

Pros:

- Rapid sealing and bundling with a 1-second tie operation thanks to inductive bag tying port.

- User-friendly interface featuring a high-definition LCD screen with bilingual support for easy operation.

- Precise control with microcontroller and stepper motor, adjustable bundling diameter and speed settings.

Cons:

- Power consumption can be relatively high at 400W, which may impact energy costs.

- Limited to specific bundling diameters (0.19-1.18 inches), which may not suit very large or small items.

- Requires a power supply of AC220V or AC110V, so compatibility depends on local voltage standards.

Automatic Twist Tie Machine with Metal Bands

The Comeacross NJJ3-28 automatic twist tie machine stands out for its all-metal construction and durable design, making it ideal for busy commercial environments that demand reliability and longevity. Built with a stainless steel winding reel, imported IC chip CPU, and a robust mechanical converter, it offers stability and precision. Its high-speed operation (70-85 ties per minute), adjustable settings, and sensitive sensors ensure consistent results. The sleek, compact design features a user-friendly touchscreen interface, automatic wire feeding, and customizable tie lengths. With a 20-year lifespan, this machine is perfect for sealing bread bags, cables, or other packaging needs in high-volume settings.

Best For: commercial businesses and industrial settings requiring efficient, reliable, and high-volume cable bundling and packaging solutions.

Pros:

- Durable all-metal construction with a 20-year lifespan ensures long-term use.

- High-speed operation of 70-85 ties per minute increases productivity.

- User-friendly touchscreen interface with adjustable settings for precise control.

Cons:

- Relatively heavy (36 pounds), which may require effort to move or reposition.

- Higher initial investment compared to manual tying options.

- Requires a power supply and may need technical support for setup and maintenance.

Tach-It 3567 Semi-Automatic Twist Tie Machine

The Tach-It 3567 Semi-Automatic Twist Tie Machine stands out for its jam-proof straight-line ribbon feed, making it an ideal choice for high-volume bakeries and food producers. Its all-metal construction guarantees durability and long service life, while its compact design—measuring just 21″ by 7″ by 12″ and weighing only 16 lbs—makes it portable and easy to use. Capable of tying up to 50 bags per minute with a semi-automatic process, it uses 25% less ribbon than competitors. Its versatility with various ribbon types and efficient operation make it a reliable, cost-effective solution for busy production lines.

Best For: high-volume bakeries, food producers, and industrial packaging operations seeking efficient, reliable, and cost-effective twist tie solutions.

Pros:

- Jam-proof straight-line ribbon feed reduces downtime and maintenance.

- Uses 25% less ribbon than competitors, lowering material costs.

- Compact, portable design with high tying capacity up to 50 bags per minute.

Cons:

- Limited to a maximum tying capacity of 1/2 inch diameter, which may not suit larger packages.

- Semi-automatic operation requires manual input for each tie, potentially slowing some workflows.

- Only operates on 110 volts (220V available), which may require additional electrical setup in some facilities.

Automatic Twist Tie Machine for Food Packaging

Designed for food packaging operations that demand speed and reliability, the automatic twist tie machine streamlines bundling and sealing tasks with electric semi-auto precision. It features a compact, durable design with a thickened aluminum shell, ensuring stability during high-speed operation. Equipped with a pressure sensor-activated curved strapping mouth, it handles wire diameters from 0-10mm and bundling sizes between 0.1-1.2mm. Capable of applying up to 40 twist ties in seconds, it boosts efficiency and reduces manual effort. Its user-friendly operation makes it easy to place products, activate automatic tying, and quickly remove secured bundles, ideal for busy food packaging environments.

Best For: food packaging facilities, supermarkets, bakeries, and craft industries seeking efficient, high-speed bundling and sealing solutions.

Pros:

- High-speed operation applying up to 40 twist ties per second for increased productivity

- Durable, compact design with thickened aluminum shell for stability and longevity

- Easy to operate with pressure sensor activation, reducing manual effort

Cons:

- Limited wire diameter capacity (0-10mm) may not suit all bundling needs

- Semi-automatic operation requires manual placement and removal of bundles

- May require training for optimal operation and maintenance

Candy Bread Twist Tying Machine with Accessories

If you’re looking for an efficient way to seal bread bags quickly and neatly, the Candy Bread Twist Tying Machine with Accessories is an excellent choice. It’s an automatic bundling device that completes ties in about one second, handling 60-75 ties per minute. The machine features a 4.3-inch LCD touchscreen with multilingual support, making control simple. It’s equipped with a stainless steel reel, adjustable from 2 to 8 turns, and suitable for diameters of 5-30mm. Comes with accessories like gold wire, white cable ties, a foot pedal, and a tool kit—perfect for bakery, grocery, or small industrial use.

Best For: small bakery, grocery store, or DIY enthusiast seeking quick and neat bread bag sealing or cable bundling solutions.

Pros:

- Fast tying speed of approximately one second per tie, increasing efficiency.

- User-friendly 4.3-inch LCD touchscreen with multilingual support for easy operation.

- Adjustable features including winding turns, step speed, and suitable diameters for versatile use.

Cons:

- Weighs around 13 kg, which may be less portable for mobile setups.

- Limited to bundling diameters of 5-30mm, not suitable for larger or smaller items.

- Requires electrical power and setup time, which may not be ideal for very quick, on-the-go tasks.

Clear Plastic Bread Bags with Twist Ties (100 Count)

Clear Plastic Bread Bags with Twist Ties (100 Count) are perfect for vendors and home bakers seeking a reliable, attractive packaging solution. These BPA-free bags measure 18x8x4 inches and come with twist ties and a date tab to keep bread fresh. The attractive wheat design enhances visual appeal, making them great for farmers markets and bakery displays. They lock in moisture, odors, and air, extending bread freshness for homemade or store-bought goods. Made from thick, durable plastic, they’re reusable and maintain their integrity after multiple uses. Suitable for all bread types, these bags offer a practical, professional packaging option.

Best For: bakers, farmers market vendors, and home bread makers seeking attractive, reliable packaging to keep their baked goods fresh and appealing.

Pros:

- BPA-free and made from thick, durable plastic for safe, long-lasting use

- Features an attractive wheat design that enhances visual appeal for customers

- Includes twist ties and a date tab for easy sealing and freshness tracking

Cons:

- May not be suitable for storing items other than bread or baked goods

- Reusable only if cleaned properly; not dishwasher safe

- Slightly larger size may be unnecessary for small bread items

Commercial Twist Tie Machine for Bag Closure

A commercial twist tie machine for bag closure is an excellent choice for busy bakeries, supermarkets, and farms that need quick, reliable sealing solutions. It offers automatic operation, tying up to 40 bags per minute, which boosts productivity and saves time. Its compact, stable design fits seamlessly into various environments, and the electric heating guarantees consistent, secure seals. Compatible with tie wires from 0.1 to 1.2mm, it’s versatile for packaging bread, groceries, or crafts. Easy to operate with minimal manual effort, this machine streamlines workflow and provides a dependable, efficient way to close bags consistently.

Best For: small to medium-sized bakeries, supermarkets, and farms seeking efficient, automated bag closure solutions.

Pros:

- High-speed operation up to 40 ties per minute for increased productivity

- Automatic tying reduces manual effort and streamlines workflow

- Compact and stable design suitable for various environments

Cons:

- Limited to tie wire diameters between 0.1-1.2mm, restricting certain applications

- Requires electrical power and heating, which may limit portability in some settings

- May need initial setup and training for optimal operation

Automatic Twist Tie Sealing Machine with Metallic Ties

The Automatic Twist Tie Sealing Machine with Metallic Ties stands out for its high-speed operation and precision, making it an ideal choice for businesses that need quick, reliable bag sealing. Its semi-automatic design, combined with PLC control, simplifies operation—just place the product, and it automatically ties and seals within 0.5 seconds. Built for efficiency, it handles bundling and sealing of bread, toys, or stationery with consistent results. The stainless steel bearings ensure smooth feeding, while its compact size makes it adaptable for various packaging environments. Overall, this machine boosts productivity while ensuring neat, secure closures.

Best For: small to medium-sized businesses in retail, bakeries, farms, and packaging industries seeking efficient, reliable bag sealing and bundling solutions.

Pros:

- High-speed operation seals ties within 0.5 seconds, greatly improving productivity.

- Easy to operate with PLC control and simple parameter adjustments.

- Compact and lightweight design adaptable to various packaging environments.

Cons:

- Semi-automatic operation may require manual placement of products, limiting full automation.

- Power requirements of 110V may necessitate specific electrical setup in some regions.

- Limited bundling diameter range (3-32mm), which may not suit very large packaging needs.

Twist Tie Machine for Bundling and Sealing

If you need a reliable solution for bundling and sealing a variety of products quickly and efficiently, this twist tie machine is an excellent choice. Its compact, lightweight aluminum housing guarantees durability and easy handling, even during frequent use. The semi-automatic design makes operation straightforward, with a pressure sensor that automatically detects tie openings for effortless bundling. Full stepper motors deliver precision, stability, and high-speed performance. It handles ties from 0.1 to 1.2 mm, perfect for packaging bread, candy, toys, and more. Plus, it comes with metallic ties and features a curved design that simplifies product placement, boosting your packaging speed and consistency.

Best For: small to medium-sized businesses, bakeries, farms, and retail environments seeking a reliable, high-speed bundling and sealing solution.

Pros:

- Durable aluminum housing ensures long-term use and easy handling.

- Semi-automatic operation with pressure sensor for effortless bundling.

- Capable of handling a wide range of tie sizes (0.1 to 1.2 mm) for versatile applications.

Cons:

- Limited to metallic ties, which may not suit all packaging needs.

- Semi-automatic operation may require some manual effort, limiting full automation.

- The machine’s size and weight may be less suitable for very tight or constrained workspaces.

Automatic Twist Tie Machine with 400W Sealing Wire

For those seeking a hands-free, highly efficient solution for bundling and sealing items, the Automatic Twist Tie Machine with 400W sealing wire is an excellent choice. It offers fully automatic operation with a sensitive sensor that detects wire supply, stopping automatically when wire runs out. The machine can handle items with diameters of 5-30 mm and tie lengths from 70-128 mm, with adjustable twists and customizable settings via a user-friendly 4.3-inch LCD touch screen. Its upgraded feed system guarantees smooth wire feeding, making it perfect for busy bakeries, packaging lines, and retail stores needing quick, consistent, and reliable bundling.

Best For: small to large-scale bakeries, packaging lines, retail stores, and industrial facilities seeking efficient, hands-free bundling solutions.

Pros:

- Fully automatic operation with sensitive sensor for seamless bundling

- Adjustable settings via a user-friendly 4.3-inch LCD touch screen for precise control

- Upgraded stainless steel feed system ensures smooth, jam-free wire feeding

Cons:

- Limited to bundling items within the specified diameter (5-30 mm) and tie length (70-128 mm) ranges

- Requires an electrical power source of 400W, which may not be suitable for very low-power environments

- Initial setup and calibration might require some familiarity with the device’s parameters

Electric Twist Tie Machine for Bundling and Packaging

An electric twist tie machine designed for bundling and packaging offers a highly efficient solution for high-volume operations, especially when quick and consistent sealing is essential. Its compact, delicate design measures 640×190×280mm and weighs only 11kg, making it easy to handle. With a 25W electric heater, it automates tie wiring, producing 40 ties per minute with adjustable settings. It’s perfect for bundling wires, cables, or packaging bread bags, candies, or crafts. Simply place the product at the tie opening, and the machine automatically tightens and cuts the tie. This reliability and speed make it ideal for supermarkets, bakeries, and packaging facilities.

Best For: businesses and individuals requiring quick, reliable bundling and packaging solutions for high-volume operations like supermarkets, bakeries, and packaging facilities.

Pros:

- Automates tying process, saving time and increasing efficiency

- Compact and lightweight design for easy handling and placement

- Produces consistent, secure ties at a rate of 40 per minute

Cons:

- Limited to wires and ties within specified size ranges (0.1-1.2mm)

- May require training for optimal operation and adjustment

- Electric-powered, so dependent on a power source and may not be suitable for remote locations

Automatic Bread Bag Twist Tie Machine with Wire Roll

The Automatic Bread Bag Twist Tie Machine with Wire Roll stands out for its high-speed, fully automatic operation, making it ideal for busy bakeries and retail stores that need efficient sealing solutions. It can tie up to 40 bread bags per second using its sensor activation, ensuring quick and consistent closures. Its compact, durable aluminum housing supports bundle diameters from 0.1 to 1.2mm, with an automatic tightening capacity of 200mm. Easy to operate, it requires minimal setup and offers reliable, stable performance. Weighing just 11kg, it’s perfect for streamlining bread packaging while saving time and labor costs.

Best For: small to medium-sized bakeries, grocery stores, and retail packaging operations seeking high-speed, automated sealing solutions for bread and small items.

Pros:

- Capable of tying up to 40 ties per second, significantly increasing productivity.

- Fully automatic with sensor activation for easy, hands-free operation.

- Compact and durable aluminum housing ensures long-term reliability and ease of use.

Cons:

- Limited to bundling diameters between 0.1 and 1.2mm, which may not suit larger packaging needs.

- Weighs approximately 11kg, which might require stable placement or additional support.

- Requires an electrical outlet for operation, limiting portability in some environments.

Electric Twist Tie Machine for Bundling and Closure

If you need a quick and reliable way to bundle and close small items, an electric twist tie machine is an excellent choice. It offers automatic operation, applying up to 40 twist ties in seconds, which notably speeds up your workflow. Its simple design makes it easy to use—just place the product at the opening, and it handles the rest. Adjustable for different bundling needs, it’s perfect for packaging bread, candy, or small products. With stable operation and high efficiency, this machine ensures neat, secure closures every time, making it a valuable addition to any packaging setup.

Best For: small business owners, bakers, and retailers seeking a quick, efficient, and reliable solution for bundling and sealing small items and packaging.

Pros:

- Fast operation, applying up to 40 twist ties in seconds to increase productivity

- Simple, user-friendly design for easy operation with minimal training

- Adjustable settings to accommodate various bundling sizes and needs

Cons:

- Limited to small items and specific bundling diameters (0.1-1.2mm)

- Requires manual placement of products for operation, which may limit automation

- May need regular replacement of twist tie rolls for continuous use

Automatic Bread Bag Twist Tie Machine

For anyone looking to streamline bread bag closures efficiently, the Automatic Bread Bag Twist Tie Machine stands out with its fast, reliable operation. Its small, sleek design makes it easy to use, with a simple panel that reduces work strain and boosts productivity. It automatically ties bags by feeding twist ties from a single roll, capable of handling sizes from 0.1 to 1.2mm. With the ability to tie up to 40 bags quickly, it saves time and improves efficiency. Built with a stainless steel bearing for smooth feeding and adjustable tension for various bag sizes, this machine is ideal for bakeries, supermarkets, and farms.

Best For: small bakeries, supermarkets, and farms seeking a quick and reliable solution for sealing bread and other packaged goods efficiently.

Pros:

- Fast and automatic operation significantly improves productivity.

- Compact, sleek design with simple controls easy to operate.

- Adjustable tension and stainless steel bearing ensure smooth feeding and versatile bag sizing.

Cons:

- Limited to bundling wire diameters of 0.1-1.2mm, which may not suit all packaging needs.

- Requires manual placement of products at the cable opening, adding a step in the process.

- No battery power needed, but reliance on electrical connection may limit portability.

Electric Semi-Automatic Twist Tie Bag Sealer

Ideal for busy bakeries and retail shops, the Electric Semi-Automatic Twist Tie Bag Sealer offers high-speed, consistent closures with a sealing capacity of up to 40 ties per minute. Its induction tying technology reduces manual effort and improves workflow efficiency. Supporting bundling diameters from 0.1mm to 1.2mm and a 200mm tightening circle, it adapts to various bag sizes. Built with durable materials, it guarantees reliable, food-safe, uniform closures. Easy to operate, it’s suitable for sealing bread, produce, and retail items. Its stable performance and minimal maintenance needs make it ideal for high-demand environments, helping streamline your packaging process effortlessly.

Best For: small to medium-sized bakeries, retail shops, farms, and food producers seeking efficient, consistent bag sealing solutions to improve packaging speed and quality.

Pros:

- High-speed operation with up to 40 ties per minute for increased productivity

- Supports a wide range of wire diameters and bag sizes for versatile use

- Durable construction ensures long-term reliability with minimal maintenance

Cons:

- Requires an electrical outlet and may need some setup for optimal performance

- Slightly heavy at 11kg, which may be less portable for mobile use

- Limited to semi-automatic operation, so manual intervention is still necessary

Factors to Consider When Choosing a Twist Tie Machine for Bread Bags

When choosing a twist tie machine, I look at how well it works with different bag sizes and materials to guarantee compatibility. I also consider how quickly and efficiently it can seal, along with how easy it is to operate. Finally, I pay attention to its durability, material quality, and whether it offers adjustable tying sizes for versatility.

Machine Compatibility With Bags

Choosing the right twist tie machine depends heavily on its compatibility with your bread bags. First, verify the machine supports the bag sizes within the required diameter range, typically from 0.1mm to 1.2mm, for a secure seal. It’s also essential that it accommodates the material type—plastic or paper—to prevent tearing or ineffective closure. Check the bundling diameter capacity, usually from 0.1 to 30mm, to match your bag sizes for proper fitting. Additionally, confirm that the machine’s adjustable tension and twist settings work well with your bag’s flexibility and desired tightness. Finally, select a machine with adjustable tie length options to ensure consistent, secure sealing across different bag sizes and packaging needs. Compatibility is key to efficient, reliable operation.

Tying Speed and Efficiency

Tying speed and efficiency are vital factors to contemplate because they directly influence how quickly and effectively you can seal bread bags. High-efficiency models can reach up to 75 ties per minute, notably boosting workflow productivity by reducing sealing time. Machines with semi-automatic or automatic operation typically tie faster and more consistently than manual models, streamlining the packaging process. The speed at which a machine feeds, twists, and cuts ties plays a key role in overall efficiency for bread packaging lines. Additionally, adjustable speed settings give operators control to optimize tying speed based on production needs and desired sealing quality. Choosing a machine that offers high tying speed and flexibility ensures you can meet demand without compromising on efficiency or seal integrity.

Ease of Operation Design

A twist tie machine with an easy-to-operate design can substantially improve your packaging process by minimizing operator training and reducing errors. Look for models with user-friendly interfaces like touchscreens or simple control panels, making it easy to learn and operate quickly. Semi-automatic and automatic machines help cut down manual effort by automatically feeding, twisting, and sealing ties, streamlining the workflow. Adjustable settings for tie length, twists, and speed allow customization without complex adjustments, saving time and effort. Visual indicators or sensors that detect material placement ensure proper operation and minimize mistakes during bundling. Ergonomic features, such as accessible controls and minimal manual handling, further enhance ease of use and reduce operator fatigue, making the entire process smoother and more efficient.

Durability and Material Quality

Durability and material quality are crucial factors when selecting a twist tie machine for bread bags, as they directly affect the machine’s longevity and performance. High-quality machines are built with durable materials like stainless steel or heavy-duty aluminum, which withstand frequent use without warping or breaking. The quality of the wire or tie material is equally important; it should be strong, flexible, and resistant to breaking to ensure secure seals. Well-made machines feature reinforced components and high-grade internal parts that reduce jamming and mechanical failure. Investing in a machine crafted from premium materials not only enhances durability but also lowers maintenance costs over time, saving you money and hassle. Ultimately, opting for quality materials means your machine will perform reliably for years to come.

Adjustable Tying Sizes

Choosing the right twist tie machine involves considering how well it can be adjusted to fit different packaging needs. I look for machines that offer customizable tying sizes, which allow me to handle various bread bag thicknesses securely. Most machines let me adjust the bundle diameter from as small as 0.1mm up to 32mm, ensuring a perfect fit every time. Being able to modify the tie length, typically between 70mm and 128mm, helps me adapt to different bag sizes and packaging styles. Additionally, adjustable turns, usually between 2 and 8, give me control over the tightness and security of each seal. An adjustable stepping speed from 5 to 100 levels helps me fine-tune the process, maintaining consistency without damaging delicate bread bags.

Power and Voltage Needs

Ensuring the twist tie machine’s power and voltage needs match your electrical setup is essential for safe and reliable operation. Most machines run on either 110V or 220V outlets, so you need to verify compatibility with your power supply. Using a machine with the wrong voltage can cause electrical issues or damage the device. Also, consider the wattage; higher wattage models often deliver more consistent tension and stronger seals. Check if the machine has adjustable voltage settings, which can help adapt to regional power standards or fluctuations. Ensuring the power requirements align with your electrical infrastructure minimizes overload risks and safety hazards. Taking the time to match these specifications guarantees smooth operation and extends the lifespan of your twist tie machine.

Maintenance and Support

When selecting a twist tie machine for bread bags, it’s crucial to take into account the level of support and maintenance options offered by the manufacturer. I look for companies that provide extensive technical support and readily available spare parts, ensuring quick repairs and minimal downtime. A good warranty is essential, as it covers potential defects and malfunctions, giving peace of mind. I also check if they supply detailed user manuals, troubleshooting guides, and training resources to handle routine maintenance confidently. Ease of access to machine components for cleaning, lubrication, and part replacement is another key factor I consider. Finally, I prefer suppliers who offer ongoing customer service, remote assistance, or on-site maintenance, helping to keep the machine running smoothly over time.

Cost and Value

The cost of twist tie machines can vary markedly, from budget options around $50 to premium models costing over $500, making it essential to weigh upfront expenses against overall value. Investing in a machine with adjustable tie length and speed features pays off long-term by handling diverse packaging needs efficiently. Machines that use fewer twist ties per closure, such as those utilizing 25% less material, help reduce operational costs and improve cost-effectiveness. Durability and build quality, like all-metal construction, add to the machine’s lifespan, offering greater value despite higher initial investments. Additionally, considering productivity rates and energy efficiency ensures you select a model that balances cost with operational benefits. Ultimately, the right choice depends on your specific volume, budget, and long-term needs.

Frequently Asked Questions

What Maintenance Is Required for Twist Tie Machines?

To keep my twist tie machine running smoothly, I regularly clean it to remove dust and debris, especially around moving parts. I check the tension and alignment of the rollers and blades to guarantee consistent tying. Lubricating the moving parts with a light machine oil every few months helps prevent rust and keeps the mechanism functioning properly. Finally, I inspect electrical components for wear and replace any worn-out parts promptly.

How Does Machine Speed Affect Packaging Efficiency?

Machine speed directly impacts my packaging efficiency by allowing me to process more bags in less time. When the machine runs faster, I can meet higher demand and reduce bottlenecks. However, I also need to balance speed with accuracy to avoid mistakes. Adjusting the speed guarantees I maintain quality while maximizing throughput. Ultimately, optimizing machine speed helps me stay productive and meet my packaging goals efficiently.

Are There Eco-Friendly Twist Tie Options Available?

Yes, eco-friendly twist tie options are available. I’ve seen brands offering biodegradable or compostable ties made from plant-based materials, which break down faster and reduce environmental impact. These options work just as well as traditional metal or plastic ties, helping you stay sustainable without sacrificing quality. If you’re looking to lessen your footprint, I definitely recommend exploring these greener alternatives—they’re a simple way to make your packaging more eco-conscious.

What Safety Features Should I Look for in These Machines?

Safety features are essential, like a seatbelt on a roller coaster. I look for machines with automatic shut-off to prevent accidents and safety guards to keep fingers away from moving parts. Anti-slip bases also help avoid slips and falls. Once, I nearly had a mishap because I ignored safety alerts—now I always prioritize machines with clear safety indicators. These features keep my workspace safe and my mind at ease.

Can Machines Be Customized for Different Bag Sizes?

Yes, machines can be customized for different bag sizes. I’ve found that many models come with adjustable settings or interchangeable parts, making it easy to handle various bag dimensions. When selecting a twist tie machine, I look for those with flexible configurations and clear instructions for adjustments. This way, I can efficiently switch between bag sizes without hassle, ensuring consistent sealing and productivity in my packaging process.

Conclusion

Choosing the right twist tie machine is like finding the perfect fit for your bakery’s needs—once it clicks, everything runs smoothly. I once struggled with hand-twisting bread bags, feeling like I was fighting a losing battle. Then I found an automatic machine, and suddenly, it was like upgrading from a bicycle to a racecar. With the right tool, your packaging process becomes effortless—making your bread look as fresh and inviting as it tastes.