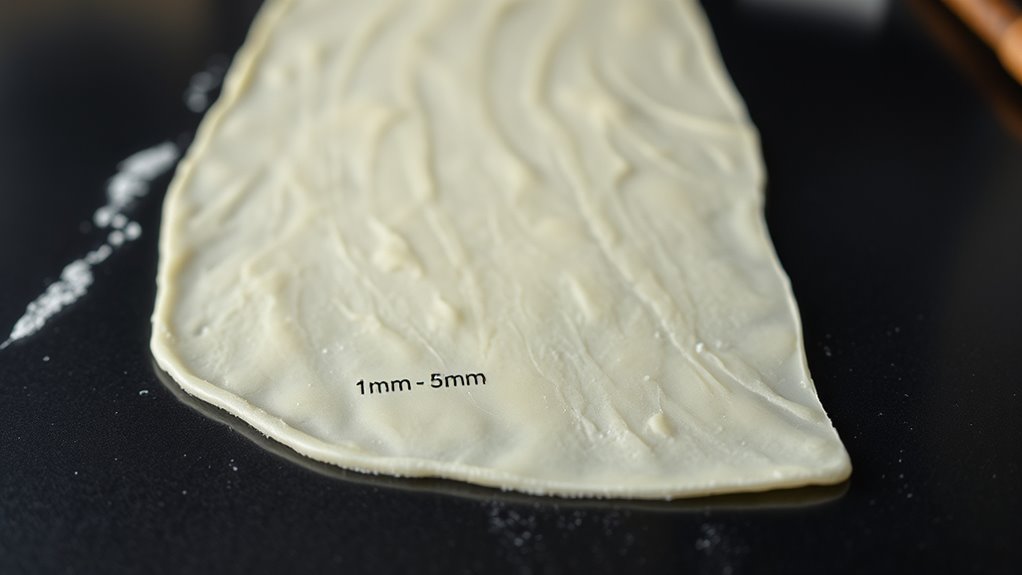

Understanding dough sheeting thickness in millimeters helps you confirm consistent results and high-quality baked goods. A 1mm dough sheet is very thin, elastic, and almost translucent, perfect for delicate pastries. Thicker doughs, around 2-4mm, give more structure and are suited for bread or sturdier pastries. Using tools like digital calipers or adjustable rollers helps you measure and control thickness precisely. Keep exploring; you’ll discover more tips for mastering dough consistency.

Key Takeaways

- Visual cues like transparency and elasticity indicate dough thickness levels, such as nearly translucent for 1mm sheets.

- Use digital calipers or rulers to measure dough in millimeters for precise thickness control.

- Thinner doughs (~1mm) are more elastic and ideal for delicate pastries; thicker (2-4mm) for bread and fillings.

- Resting dough relaxes gluten, promoting uniform thickness and preventing stretching during sheeting.

- Consistent pressure and guided rollers ensure uniform thickness across the entire dough sheet.

What Is Dough Sheeting and Why Does It Matter?

Dough sheeting is the process of rolling out dough into a thin, uniform sheet, which is essential for achieving consistent texture and appearance in baked goods. This technique relies on dough elasticity, allowing you to stretch and shape it without tearing. Proper gluten development is critical here because it gives the dough the strength and flexibility needed for sheeting. When gluten strands are well-developed, the dough becomes more elastic, making it easier to roll out smoothly and evenly. If the gluten isn’t properly developed, the dough can tear or become uneven, ruining the final product’s appearance and texture. Mastering dough sheeting ensures uniform thickness, which is indispensable for consistent baking results and a professional finish.

Why Do Millimeters Matter in Baking Measurements?

Precise measurements in millimeters are vital in baking because even small variations can considerably affect the final product’s texture, appearance, and consistency. When dough is too thick or thin, it impacts dough elasticity and gluten development, which are essential for structure and chewiness. Using accurate millimeter measurements guarantees proper dough handling and uniform baking results. For instance, precise measurement techniques ensure that each sheet of dough meets the desired specifications, leading to consistent quality in baked goods. Proper rolling methods help achieve uniform thickness across different batches. Additionally, maintaining consistent dough consistency is critical for achieving the intended texture and appearance. For example:

| Thickness (mm) | Effect on Dough |

|---|---|

| 1 mm | Very delicate, fragile dough |

| 3 mm | Ideal for delicate pastries |

| 5 mm | Suitable for general sheetings |

| 7 mm | Slightly thicker, firmer dough |

| 10 mm | Heavy, less pliable dough |

What Does a 1mm Thick Dough Look Like?

Have you ever wondered what a 1mm thick dough actually looks like? At this thinness, your dough should be quite delicate yet still manageable. It typically exhibits good dough elasticity, allowing you to stretch it without tearing easily. Proper gluten development is key here; it creates the strength needed to handle such a fine sheet without ripping. When you hold the dough up to the light, it appears almost translucent, revealing a smooth, even surface. You might notice slight tension when you lift it, indicating adequate elasticity. This thickness is common for delicate pastries or layered doughs. Keep in mind, the dough’s elasticity and gluten structure determine how well it maintains this thinness without tearing or becoming overly sticky.

How Do Thin and Thick Doughs Compare?

When comparing thin and thick doughs, the differences become clear in their texture, handling, and purpose. Thin doughs are more delicate, with higher dough elasticity that allows them to stretch easily without tearing. They require well-developed gluten for strength and flexibility, making them ideal for pastries or wrappers. Thick doughs, on the other hand, are sturdier, less elastic, and easier to handle for shaping or filling. They often have less gluten development, resulting in a denser texture.

Thin doughs are delicate, elastic, and ideal for pastries; thick doughs are sturdy, less elastic, and better for shaping.

- Thin doughs are more elastic, ideal for delicate pastries

- Thick doughs offer more structure and stability

- Gluten development is essential for elasticity in thin doughs

- Thick doughs are less prone to tearing during handling

- Texture differences impact their specific culinary uses

How Can You Measure Dough Thickness Accurately?

To measure dough thickness accurately, you need the right tools and techniques. Start with a ruler or a digital caliper for precise readings in millimeters. Make sure the dough has proper dough elasticity; if it’s too stiff or too soft, measurements can be inconsistent. Use gentle, even pressure when pressing the tool onto the dough to avoid distortion. Temperature control is vital—warm dough may be more pliable, affecting thickness, while chilled dough remains firmer. Before measuring, allow the dough to reach a consistent temperature and rest if needed. Take multiple readings across different areas to account for uneven sheeting. This approach guarantees more reliable measurements, helping you achieve the desired thickness for your recipes. Additionally, understanding how to master the art of bug out bags can ensure you’re prepared for emergency situations where precise measurements and efficient packing are crucial. Proper measurement techniques also involve understanding the importance of consistent dough handling, which impacts the overall accuracy of your thickness assessments, as well as the importance of maintaining proper dough temperature for consistent results. Moreover, being aware of proper dough elasticity can help maintain uniform thickness during rolling and sheeting.

Can You See These Dough Thickness Examples in Different Recipes?

Different recipes demand specific dough thicknesses to achieve the best results. You can often see these variations in practice, especially when considering dough elasticity and gluten development. Thinner doughs, like for pastries or crackers, require minimal gluten development for crispness and flexibility. Thicker doughs, such as for bread, need more gluten to support rise and structure. Here are some examples:

- Pizza dough (2-4 mm): moderate gluten development for elasticity

- Pastry dough (1-2 mm): minimal gluten, delicate texture

- Pasta sheets (0.5-1 mm): high gluten development for strength

- Flatbread (3-5 mm): balanced gluten for flexibility

- Croissant dough (1-2 mm): well-developed gluten for layers

Seeing these examples helps you understand how dough thickness impacts elasticity and gluten formation across recipes.

How Does Dough Thickness Affect Texture and Quality?

Dough thickness directly influences the final texture and overall quality of baked goods. When you roll dough too thin, it can lose its dough elasticity, resulting in a fragile or brittle crust. Conversely, a thicker dough allows for better gluten development, which provides structure and chewiness. Proper thickness guarantees that gluten strands form evenly, creating a balanced texture. If the dough is too thick, baked goods may be dense or doughy, while overly thin sheets can produce a dry or crumbly outcome. Achieving the right thickness helps you control moisture retention and airflow during baking, leading to improved crust crispness or tenderness. Additionally, understanding the importance of consistent dough thickness** ensures uniform baking and predictable results. Being aware of heat distribution and material properties can further enhance your ability to bake with precision. Recognizing how material properties influence heat transfer can help you select the optimal baking tools and techniques. Moreover, maintaining thickness uniformity across the dough surface is crucial for consistent baking performance and high-quality results. Incorporating techniques such as measuring tools** can help achieve this consistency more reliably. Ultimately, understanding how dough thickness impacts these elements lets you craft baked goods with the desired texture and high-quality results.

What Tools and Techniques Help Achieve Precise Thickness?

Using the right tools makes it easier to achieve consistent dough thickness, whether it’s a rolling pin with adjustable rings or a dough sheeter. Techniques like controlling pressure and rotating the dough regularly help maintain uniformity. By combining these tools and methods, you can guarantee precise, even sheets every time.

Tools for Precise Thickness

To achieve consistent dough sheeting thickness, precise tools and techniques are essential. These help manage dough elasticity and guarantee uniformity, especially during fermentation control. Using adjustable rollers or sheeters allows you to set specific millimeter measurements, maintaining consistent thickness throughout. A digital caliper offers precise measurement, helping you verify thickness quickly. A dough scraper or bench knife helps shape and smooth dough edges, reducing unevenness. Proper hydration and fermentation management contribute to ideal dough elasticity, making it easier to sheet evenly. Additionally, a textured surface or silicone mats can prevent sticking and uneven spreading, aiding in uniform thickness. Combining these tools and techniques ensures you control every stage, resulting in a perfectly sheeted dough every time.

Techniques for Consistency

Achieving consistent dough thickness relies heavily on effective techniques and the right tools. One key method is managing dough elasticity; properly rested dough holds a uniform shape, making it easier to sheet evenly. Developing gluten is essential, so knead your dough adequately to create strong, resilient gluten networks that resist tearing during rolling. Use a consistent pressure when rolling, applying even force to avoid uneven thickness. Incorporate guides or thickness rollers to maintain precise measurements. Resting the dough between rolls helps relax gluten, reducing elasticity that causes uneven sheeting. Additionally, using a bench scraper or ruler can help monitor thickness throughout the process. Mastering these techniques ensures your dough maintains consistent thickness, resulting in professional-quality results every time.

How Do You Adjust Thickness for Different Pastries and Breads?

To get the right texture, you need to adjust your dough thickness based on the pastry or bread you’re making. For puff pastry, you’ll want a thinner sheet to guarantee proper layers, while thicker dough works better for bread. When making bread crumbs, a very thin sheet helps create uniform, fine crumbs.

Adjusting for Puff Pastry

Adjusting the dough sheeting thickness for puff pastry involves more than just setting the machine to a specific measurement. You need to account for the dough’s elasticity and layering process to guarantee a flaky, light texture. If the dough is too thick, it won’t puff properly; too thin, and it might tear or collapse. Using proper dough elasticity techniques helps ensure consistent puffing and layering.

- Use a slightly thicker setting initially to maintain dough elasticity during lamination

- Chill the dough between sheeting to improve layering and puffing

- Gradually decrease thickness, monitoring the dough’s responsiveness

- Keep the dough evenly rolled to prevent uneven puffing

- Test a small batch to calibrate the ideal thickness for your specific recipe

Thickness for Bread Crumbs

The thickness you choose for bread crumbs considerably affects their texture and how they perform in different recipes. Thinner crumbs, around 1-2 mm, create a finer, more uniform coating ideal for delicate dishes like schnitzel or breaded fish. Thicker crumbs, 3-4 mm, offer a crunchier texture suitable for casseroles or topping baked dishes. Adjusting thickness depends on dough density and ingredient ratios; denser doughs often produce firmer crumbs that hold their shape better. Lighter doughs with higher hydration may require thinner crumbs to prevent clumping. Consider the recipe’s final texture: for a crispy finish, opt for slightly thicker crumbs, while finer crumbs work better for smooth, even coatings. Tailoring the sheeting thickness accordingly ensures excellent bread crumb performance in your baked and fried creations. Additionally, understanding the sheeter settings helps achieve consistent thickness and optimal results. Properly calibrated settings contribute to uniformity, making your breading process more predictable and efficient. Furthermore, being aware of industry standards for sheet thickness can help maintain quality and consistency in your products.

How Can You Maintain Uniform Dough Thickness Every Time?

Achieving consistent dough thickness requires attention to detail and proper technique. First, guarantee your dough has ideal dough elasticity; over- or under-processed dough can lead to uneven sheets. Be mindful of fermentation effects, as over-fermented dough becomes slack, making it harder to control thickness. Use a calibrated rolling pin or sheeter to maintain steady pressure. Rest dough between rolls to prevent sticking and unevenness. Keep your work surface clean and dusted lightly with flour to reduce sticking. Regularly check your dough’s thickness with a ruler or gauge to catch any inconsistencies early. Additionally, incorporating visual cues can help you better judge dough thickness during the rolling process. Paying attention to nanotechnology advancements can also inspire innovative tools and techniques for more precise dough handling and processing.

Frequently Asked Questions

Can Dough Thickness Influence Baking Time and Temperature?

Yes, dough thickness can influence baking time and temperature. Thinner dough heats more quickly, so you may need to reduce baking time or temperature. If your dough has good elasticity and you use proper rolling techniques, you can achieve consistent thickness, guaranteeing even baking. Thicker dough may require longer baking at a slightly higher temperature to ensure thorough cooking. Adjust based on dough elasticity and your rolling methods for best results.

Are There Safety Considerations When Rolling Dough to Very Thin Levels?

Rolling dough too thin can be a safety hazard, so pay attention. You risk dough tearing or creating uneven surfaces that could cause it to break apart unexpectedly. Be cautious, as thin dough can be as fragile as glass, and applying too much pressure may lead to injuries or compromised baked goods. Always use gentle, even pressure and check your dough frequently to prevent accidents.

How Does Ambient Temperature Affect Dough Thickness During Preparation?

Ambient temperature directly impacts dough thickness during preparation. If it’s warm, your dough becomes more elastic, making it harder to roll thinly without tearing. Conversely, cooler temperatures preserve dough elasticity and help you achieve a consistent, even thickness. To maintain control, work in a moderate environment, and chill your dough if it warms up too much, ensuring easier rolling and better sheet thickness.

What Are Common Mistakes That Alter Dough Thickness Unintentionally?

You often unintentionally alter dough thickness through unevenness caused by inconsistent rolling pressure. When you apply too much pressure in one spot, it creates unevenness, making parts thicker or thinner. Not maintaining steady pressure or rushing the rolling process also leads to inconsistent dough thickness. To avoid this, guarantee even pressure and regularly check your dough’s thickness, using a visual guide if needed, so your final product stays uniform.

Does Dough Thickness Impact the Caloric Content of Baked Goods?

Dough thickness is like a secret ingredient that influences the caloric density of your baked goods. Thinner dough means more surface area, so it can pack more calories per bite, impacting the nutritional profile. Conversely, thicker dough reduces calorie concentration, affecting nutritional impact. So, paying attention to thickness can help you control not just texture but also the overall calorie content of your treats.

Conclusion

Mastering dough sheeting is key to perfect baked goods. Did you know that even a 1mm difference in thickness can change your pastry’s texture? By using proper tools and techniques, you can guarantee consistent results every time. Remember, precise measurements lead to better quality and uniformity. So, invest in your skills—you’ll enjoy more professional-looking, delicious baked treats that impress every time!